McCoy Global winCATT®

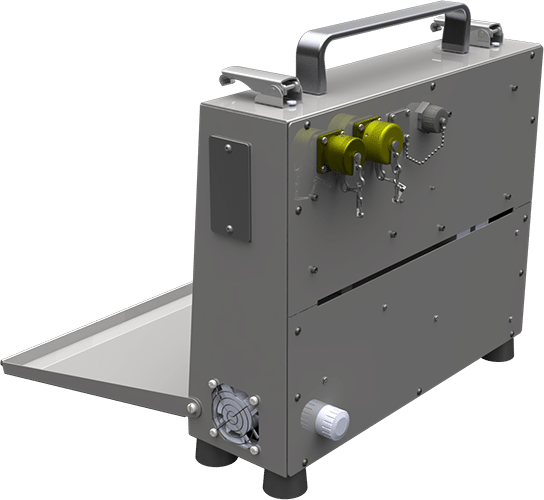

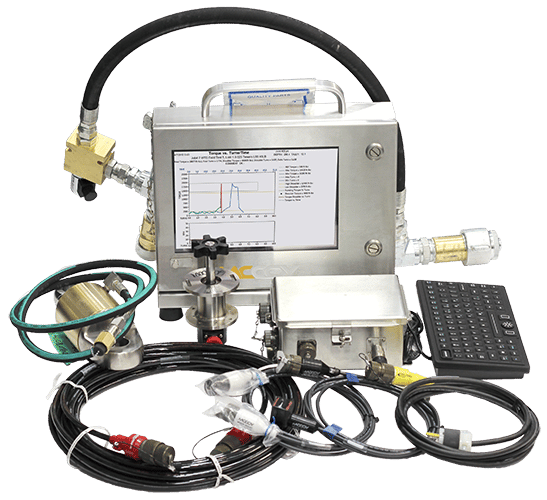

winCATT®Torque Turn System

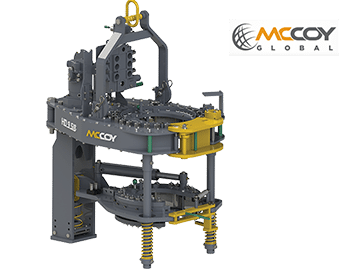

Monitor and control tubular connection power tong make-up reliably, accurately, and easily with WINCATT®.

WINCATT® is a software tool that interacts with external control hardware to provide real-time monitoring and control of tubular connection power tong make-up. It allows you to easily specify make-up parameters, control the make-up process, and evaluate quality.

Using the software, you can monitor torque, turns, and rotational speed during make-up. You have the option of controlling speed during make-up as well. Controls are based on either final torque or final turns.

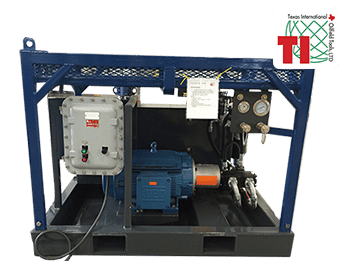

WINCATT® Torque Turn Monitoring System comes with:

- Calibration management system

- Automatic “Start Recording” and “Dump Valve Release”

- Automatic descriptive comments with optional override

- Optional pressure test system is available

WINCATT® increases the safety of your people and gives you the information you need to ensure make-up conforms to manufacturers’ specs. You can review results from previous make-ups and create a number of reports for further analysis and information.

.

.