All About Drill Pipes: What are They & What are They Used For?

Drill pipes are essential and versatile tools for drilling and natural resource exploration. They are critical across many industries, from deep well drilling in the oil and gas industry to mineral extraction and geothermal development. Despite their importance, drill pipes are frequently underappreciated in discussions about essential oilfield equipment.

We aim to address this issue! Below, we will take a closer look at drill pipes, exploring aspects such as their classification, applications and sizing.

Whether you’re an industry stakeholder or just curious about the machinery driving resource exploration, this post provides a clear guide to understanding drill pipes and their various functions.

What is a drill pipe?

In the field of drilling, where extracting valuable resources from beneath the earth’s surface is a crucial and intricate task, a drill pipe plays a key role.

A drill pipe is a seamless tube manufactured to endure the rugged and challenging conditions encountered in drilling operations. This seamless design process guarantees longevity, minimizing the risk of weak points that might undermine the pipe’s structural integrity. They come in a variety of sizes, strengths, and wall thicknesses.

A drill pipe typically constitutes a large portion, usually around 95%, of what is known as the ‘drill string’. Read on for more information on drill strings!

A key characteristic of a drill pipe is its hollow interior. The fact a drill pipe is hollow is essential for drilling because it lets fluid flow through the pipe.

What is a drill pipe used for?

A drill pipe has two main functions:

- Torque Transmission: Drill pipes are designed to transfer drilling torque over long distances, often spanning several miles, from the drilling rig’s surface down to the drill bit.

- Fluid Circulation: A drill pipe serves as a conduit for drilling fluid, also known as ‘drilling mud’, allowing it to flow down from the surface and back up the wellbore. Drilling fluid is crucial for cooling the drill bit, carrying cuttings to the surface, and maintaining pressure in the well.

Given the substantial depths reached in drilling operations, which can extend up to nearly 15,000 feet, connecting different drill pipe sections is necessary. This connection process typically involves welding together threaded tool joints, including the box tool joint and the pin tool joint, to create a continuous length of drill pipe.

What are drill strings?

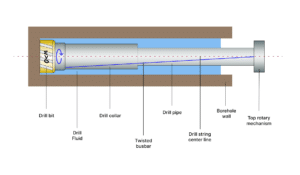

A drill string is the interconnected assembly of various components used to bore into the ground or seabed for resource extraction purposes. Drill strings can vary in length and composition depending on the depth and complexity of the drilling operation. They usually comprise multiple drill pipes, tool joints, drill collars, and the drill bit itself.

What materials are used in drill pipes?

Drill pipes made out of steel are the most common. The specific steel alloy used is typically high-strength, low-alloy steel (HSLA). This type of steel is chosen for its ability to withstand the harsh conditions encountered during drilling, including high-stress levels, corrosion, and wear.

Aluminum is also occasionally chosen, due to its light-weight characteristic. Aluminum pipes are well-suited for situations where weight is a critical factor, such as remote drilling or when equipment weight limitations need to be considered.

In some cases, drill pipes may be coated with materials like nickel or other anti-corrosion coatings to provide additional protection against corrosion.

Drilling pipe classification

After inspection, drill pipes are categorized into one of three classes:

- N-Class (New Pipe): These are the strongest and newest pipes available, typically in excellent or near-pristine condition.

- P-Class (Premium Pipe): Premium pipes are a step down from N-Class. They have experienced some wear but are still highly functional.

- C-Class (Used Pipe): C-Class pipes further subdivide into C-1, C-2, and C-3, depending on their condition. They range from well-worn pipes to those nearing the end of their serviceable life. The specific rating indicates the extent of wear and longevity, making C-Class pipes suitable for less demanding drilling tasks.

Once a pipe is no longer usable, it gets marked with a red band and assessed for scrap. Drill pipes can be expensive, so they are often reused.

Types of drilling pipes

Drill pipes vary, tailored to specific drilling needs. Common types include regular and heavyweight drill pipes, with spiral pipes for enhanced torque transmission and speciality pipes for directional and horizontal drilling.

Understanding these different types of drilling pipes is essential for selecting the right tools and equipment to optimize drilling efficiency and effectiveness in diverse geological conditions.

Regular drill pipe

A regular drill pipe, or standard drill pipe, comes in various sizes and outer diameters. The most common outside diameter for regular drill pipes ranges from approximately 2 3/8 inches to 6 5/8 inches.

Drilling pipes are typically manufactured in standard lengths, with the most common options being 30 feet (9 meters) and 45 feet (14 meters). Longer lengths may be used for deeper drilling projects.

Many regular drill pipes have a center upset or thick wear pads. These features prevent the outer surface of the drill pipe from grinding against the rough walls of the borehole. Center upsets reduce wear and friction, prolonging the lifespan of the drill pipes.

Heavy weight drill pipe

A heavy weight drill pipe (HWDP) is characterized by its thicker walls and significantly higher weight per foot (lb/ft) compared to regular drill pipes. These attributes make a heavy weight drill pipe exceptionally well-suited for demanding drilling applications.

HWDP is designed to address challenges like borehole control, wellbore stability, and high-pressure environments in deep drilling. Its added weight helps maintain drilling accuracy.

How are the sizings of drill pipes measured?

To determine the sizing of drill pipes, each individual joint is referred to as a ‘Single’ and categorized further by its length, typically using a three-part API length range classification: one, two, or three. The most common length for drill pipes is “range two,” a crucial factor when calculating drilling depth as it encompasses the entire drill string, including the drill pipe.

Drill pipes come in various sizes and materials, ensuring a suitable option for every project. Similarly, API classes group drill pipes based on size and material, assessing factors like yield strength, tensile strength, the drill-pipe body, and the tool joint. API classes are assigned through rigorous inspections, with a particular emphasis on evaluating used drill pipes.

How strong is a drill pipe?

The strength of a drill pipe varies depending on several factors, including its material, size, and design. As mentioned, drill pipes are manufactured from HSLA, which provides exceptional durability and resistance to the extreme conditions encountered in drilling operations.

The strength of a drill pipe is often expressed in terms of its tensile strength, which can range from 100,000 pounds to well over 1,000,000 pounds per square inch (psi), depending on the specific type and grade of the pipe. Heavyweight drill pipes (see above!) have higher tensile strengths than regular drill pipes. The strength of a drill pipe is a critical factor in its ability to transmit torque, withstand axial loads, and endure the rigors of drilling at various depths and in diverse geological formations.

How to maintain and inspect drill pipes

Maintaining and inspecting drill pipes ensures their longevity and safe performance in drilling operations. Regular maintenance involves cleaning, protecting against corrosion, and monitoring wear and tear.

Prior to each use, a thorough visual inspection is essential, checking for cracks, deformations, or other signs of damage. Non-destructive testing (NDT) methods, such as magnetic particle testing (MPT) or ultrasonic testing (UT), can be employed to detect internal flaws. Regularly inspecting the threaded connections for wear and ensuring they are properly lubricated is crucial. Additionally, monitoring the center upsets and wear pads can help prevent excessive friction and prolong the drill pipe’s lifespan.

How can TIOT help you?

Determining the proper drill pipe for your drilling project can be a difficult choice to make. Luckily, our drilling experts are available to answer questions on your drilling tool selection. Give us a call for answers today!

.

.