What is a Top Drive System?

If you’re interested in drilling, rigs, and wells, you’ve probably heard of Top Drives – but what actually are they? Let’s start with a definition:

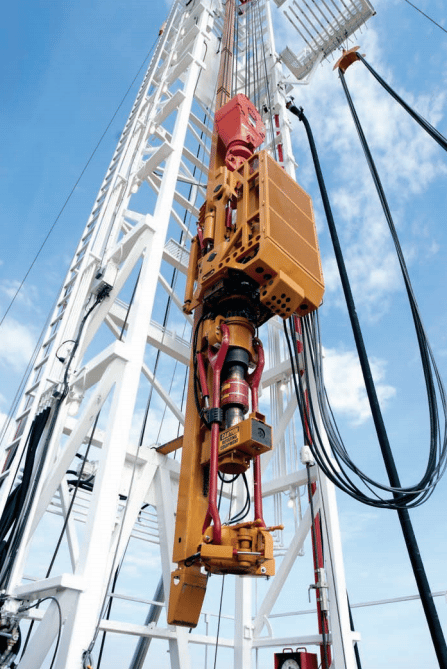

A Top Drive is an essential piece of drilling equipment; it is basically a large motor system which is hoisted in a derrick, mast or drilling rig. Top Drives can be used in a variety of rigs including truck-mounted rigs and offshore rigs.

Now that you understand Top Drive basics, let’s dive into some more detailed information.

Benefits of Top Drive Systems

Top Drive Systems have a plethora of benefits! Like we mentioned above, one of the most substantial benefits of this system is that they can be easily installed on any mast or derrick. Top Drive Systems also work as replacements for Rotary Officers and Kelly Systems – meaning there are fewer systems and parts to keep track of.

Top Drives are also extremely safe. Because their operation can be handled remotely, there is no need for rig workers to directly deal with this heavy equipment. Additionally, Top Drives can provide the necessary torque needed to tighten connections and can pierce 90-foot sections, which reduces connection and monitoring time, as well as provides improved directional control.

Components of a Top Drive System

The following list is an inclusive explanation of Top Drive System components:

- Torque Track

- Optional Swivel

- Torque Bushing

- Swivel Sub

- Extend Frame

- Quill

- Mainframe Assembly

- Load Nut

- Pipe Handler Assembly

- Tilt Assembly

- Stabbing Valve

- Saver Sub

- Grabber Assembly

- Bail Assembly

- Elevator

Differences Between Top Drives and Kelly Systems

Top drives start the necessary rotation that is needed to move the drill stem. This means that a Kelly System and Kelly bushing are not required for Top Drive Systems; rather, a master bushing and a rotary table should be used for support. Mast bushings and rotary tables will support the weight of the slip and drill stem, and also serve as a conduit for the drill stem to be lowered or raised into a wellbore.

Because a Kelly System is not necessary, the length of each strand is longer than normal and makes up more than a single joint. When you drill with a Top Drive, you can expect the stand of the drill pipe to be composed of three drill pipe joints. This means that Top Drives can drill about 90 feet before making a connection, whereas with a Kelly System, you will make a connection at about 30 feet deep.

Another difference between a Kelly and a Top Drive is that a Top Drive System allows rotation and circulation while back reaming out of a hole. Kelly Systems do not have this capability and cannot rotate the drill stem.

Now that you understand what a Top Drive System is, how it differs from a Kelly System and what the benefits of Top Drives are, give us a call today to purchase one for your drilling site.

.

.