AllTorque Control Systems

AllTorque Control Systems

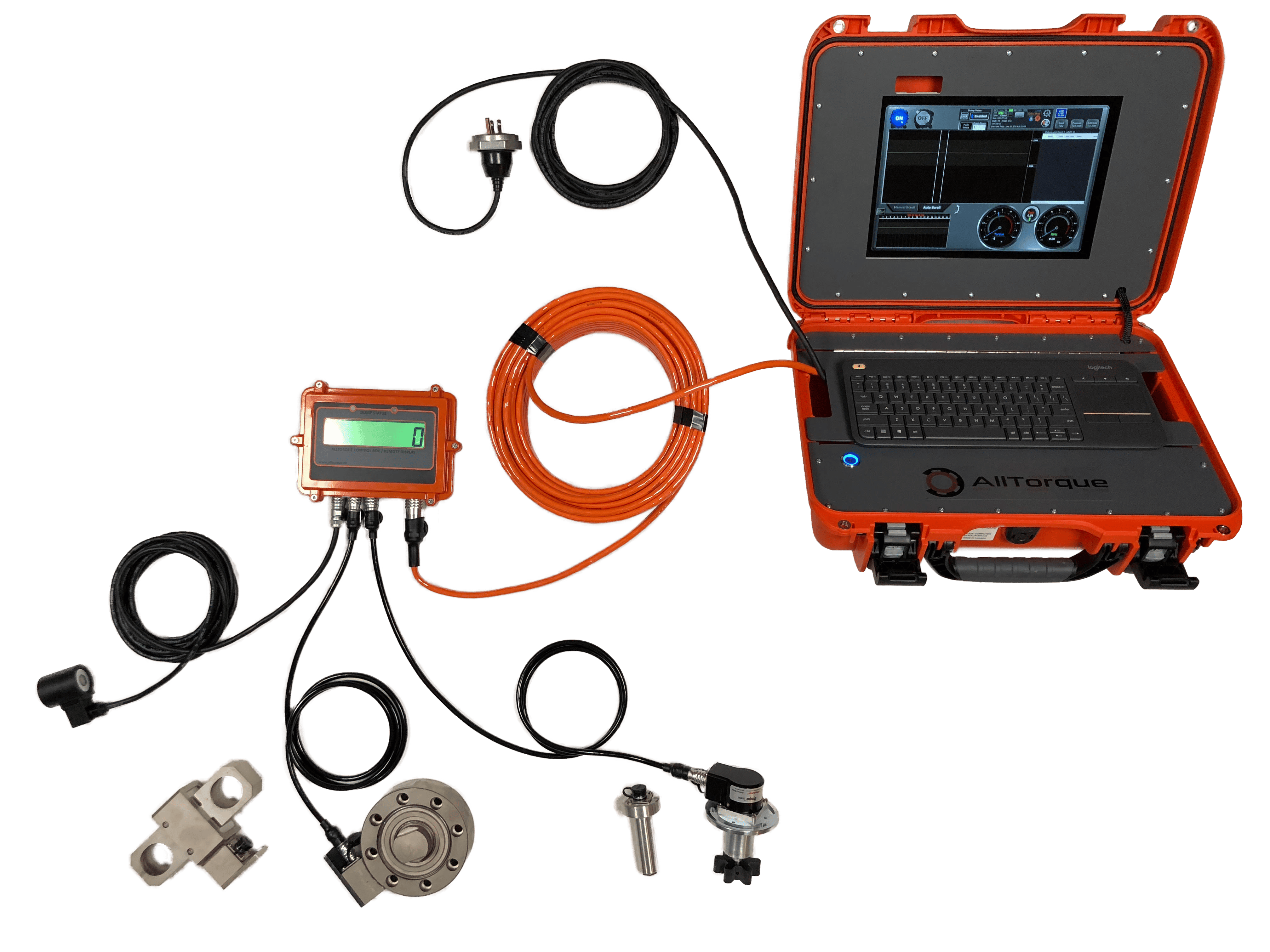

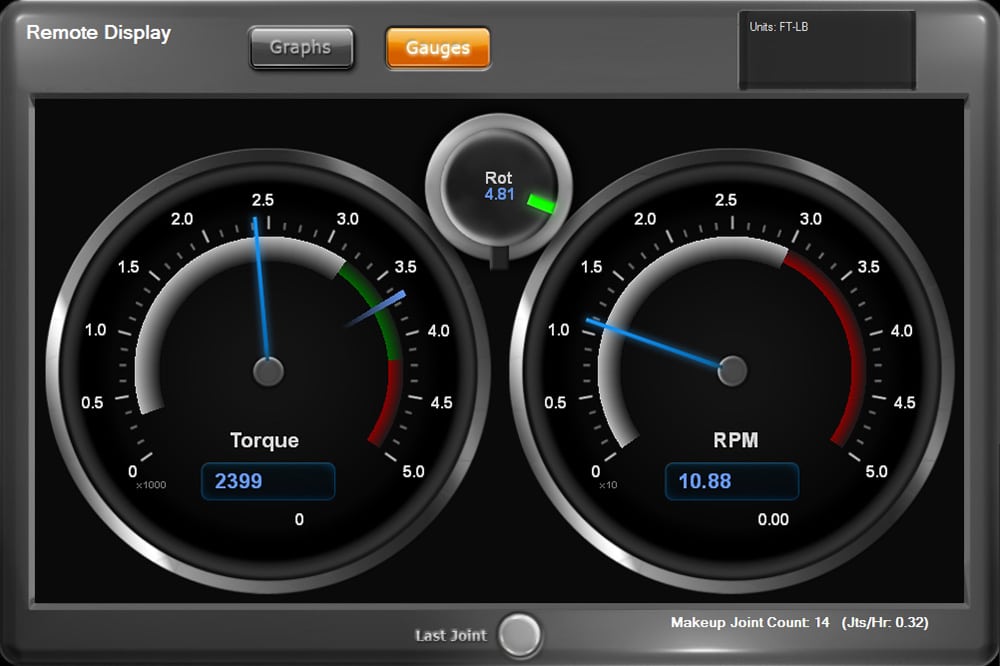

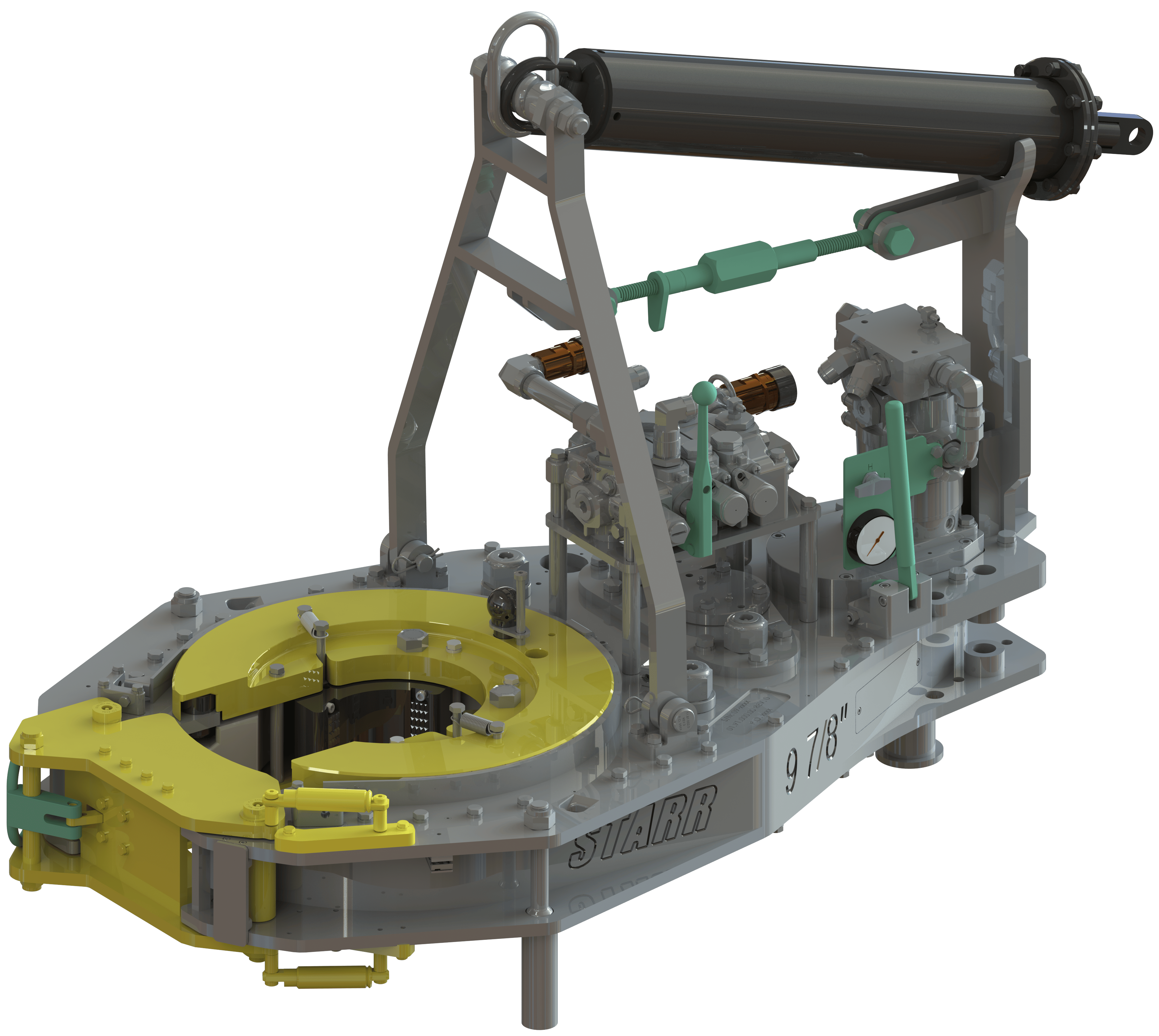

Monitor and Control Torque, Turns, & RPM during casing Makeup or Breakout.

Reliable

Hardware built to handle rig floor environment / Most robust load cells / Real Time data backup through the AllTorque-Cloud*. Fail safe hardware design with battery backup. All data is Encrypted for security and integrity

- 10+ years of development

- TLS 1.2 Security & B-Krypt Encryption

- Designed with latest available hardware

- Constant software updates to ensure bug fixes and industry requirements are always met

- Data is stored for 40 years (37 years in deep storage)

- AllTorque Service Plan includes yearly load cell calibration, so no more out of date load cells

Accurate

Load cells calibrated to < 0.1%, then we sample at the highest rate in industry > 3000Hz, No need for a UPS on rig power either, as all that stuff is baked right into all our systems.

- Load cell design is the most stable in the industry

- Hardware is real fast, running at idle it is still the fastest in the industry

- Stable readings by adding power backup and power filtering into all of our systems

- Constant software updates ensure bug fixes and industry requirements are always up to date

- We are working on engineered ways to correct sensor calibration and eliminate user error.

Easy to Use

Clean user interface that is constantly being updated with new features and easier to use setup

Modular hardware components that are plug and play and updated as needed

Step By Step guides built in, with 24/7 phone & online support

- Syncing via the AllTorque-Cloud makes Pre & Post job tasks Easy*

- Never lose data with AllTorque-Cloud online backup*

- Real-Time monitoring jobs with an internet connection*

- Pipe library’s, Tong library’s, Load Cell library’s all Sync’d*

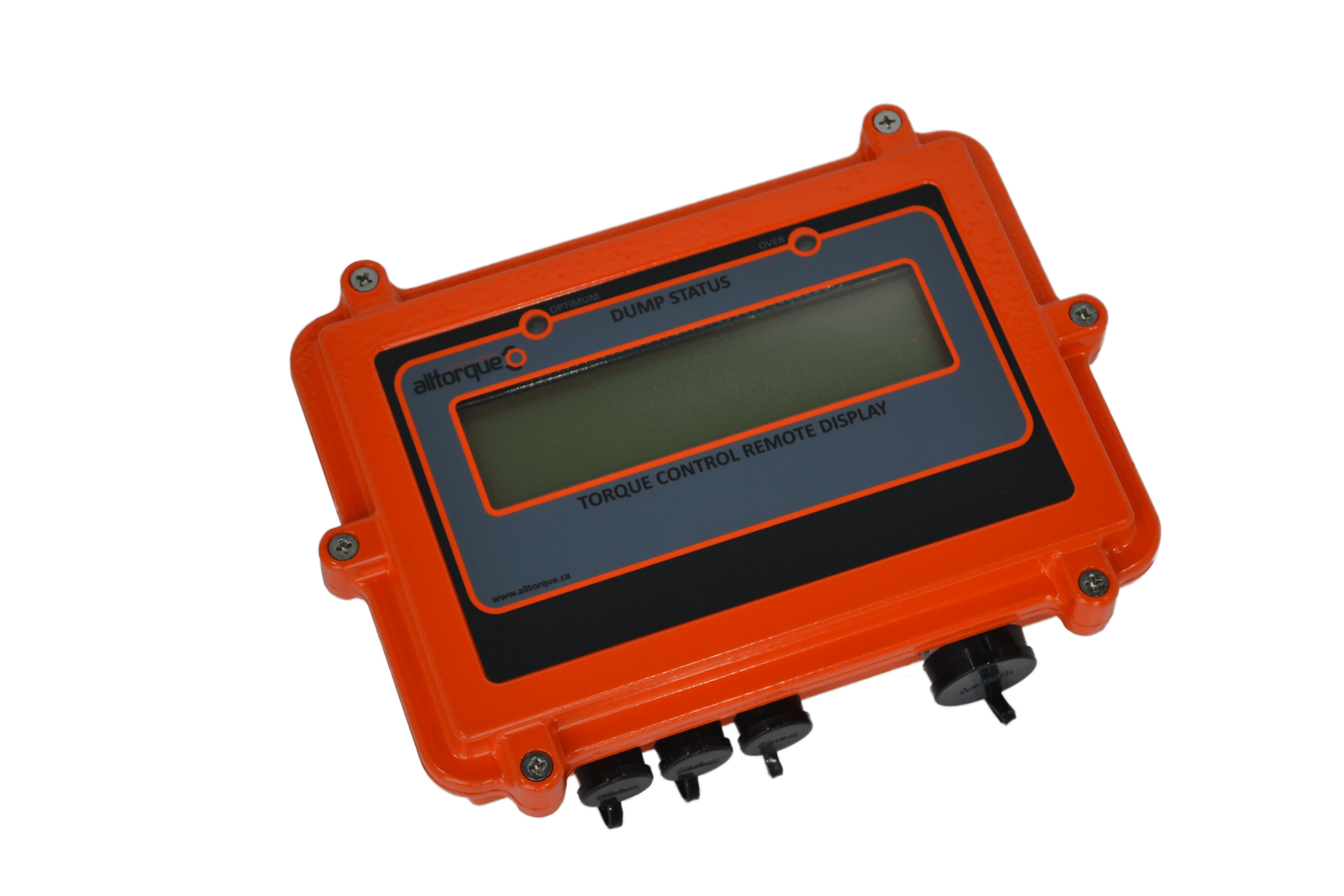

- Control Box digital readout for tong operators

- Rig Floor Secondary Monitor for Thread Reps**

*Internet Connection is required (no minimum speed requirement)

**Not included in the base systems, must be ordered separately

.

.